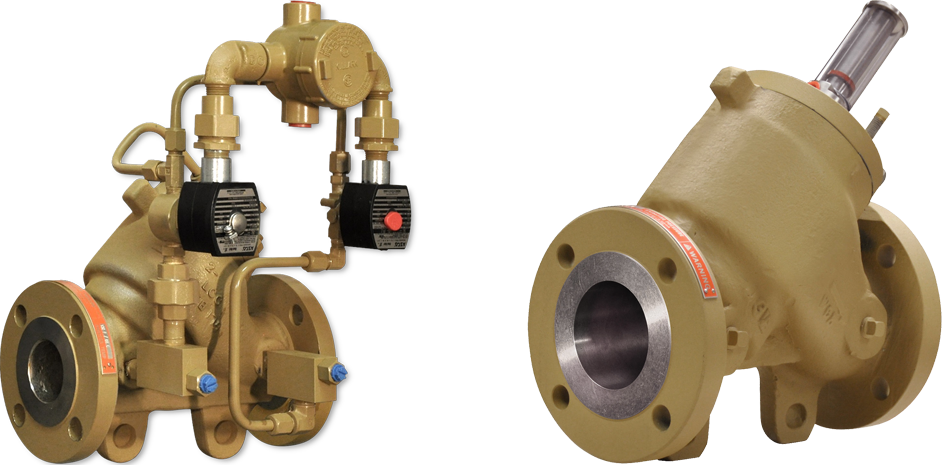

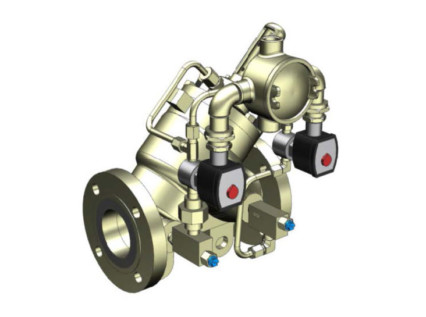

Piston Style Control Valves

Applications:

- Batch Control

- Pump Differential Pressure Control

- Down Stream Pressure Reducing

- Meter Over-Pressure Protection

- Pipeline Delivery to Storage Tanks

- Pump Suction Pressure Control

- High Level Shut Off Control

- Remote On / Off Blending

- Distribution Systems

- Flow Control

- Back Pressure Control

- Pump By-Pass

- Vapor Pressure Control

Specifications:

- Line Size: 2″ to 16″ (N50 to DN400)

- Fluid Type: Liquid

- Temperature Range: -15° F to 150° F (High and Low Temp Options Available)

- Operating Pressure Range: ANSI 150 to 900 (Higher Operating Pressures Available)

- Materials (Valve Body): Carbon Steel, ASTM A352 GR LCC

- Materials (Valve Cylinder):

- 2″ to 4″ (DN50 to DN 200): Stainless Steel, ANSI 150 to 600

- 6″ to 16″ (DN250 to DN 400) Carbon Steel, Nickel Coated, ANSI 150 to 600

- Valve Piston Materials: Standard: Stainless Steel

- O-Ring Materials:

- Standard: Viton Dynamic and Buna-N Static

- Optional: Neoprene, EPR, Viton GFLT, all Buna-N, Kalrez® / Teflon AP (Aggressive Products)

- Pilot Materials: Standard: Carbon Steel

- Tubing & Fittings: Standard: Stainless Steel

- Voltage Options: 12 VDC, 24 VDC, 110 / 120 VAC, 220 / 240 VAC

Features:

- 45° Valve design ensures high capacity with a low pressure drop

- ANSI Class 6 Rating insures zero seat leakage

- Valve design inherently prevents reverse flow

- Universal valve parts allow for a reduced spare part inventory

- Simple design with no diaphragm or stuffing boxes reduces repair time

- A.P. Elastomers and coating options available to meet aggressive product applications

- Valve pilots can control pressure in a range of 10 to 1,440 PSI (+/-2 PSI)

- Large internal pilot ports available for high pressure applications

- Pre-wired solenoids can be added to the valve for flow control / loading applications

- Opening / Closing speed control options available to eliminate valve slam

- Pre-plumbed digital valve / pilot kits available to reduce field down time

- Strainer / Needle valve installed on the control loop helps ensure clean product goes to the pilot / solenoids

- Valves can be equipped with customer specified parts like a Rexa Actuator

Few valves provide the level of functionality and performance that a piston style control valve does. Its linear flow characteristics, high Cv, and low pressure drop make it well-suited for most pipeline, load rack, or batching applications. Its external control loop can be configured to provide several functions using the same valve.

Most configurations are driven by hydraulic pressure and do not require an external power source or input signal. Piston style valves can be configured for applications ranging from crude oil to LPG. With decades of reliable service in the petroleum industry, the piston style valve is well-suited for virtually any control application.

Documents & Additional Information

Daniel Control Valves: Precaution on Valve Sizing

Daniel Model 700A Series Control Valve Manual, Sizes 2″ to 12″

Daniel 700B Series Control Valve Manual, Sizes 2″ to 16″

Daniel 710, 720, 750, 754, 760, 770 Control Valve Data Sheet, Sizes 2″ to 16″

Daniel Model 788 Digital Control Valve Manual, Sizes 2″ to 8″