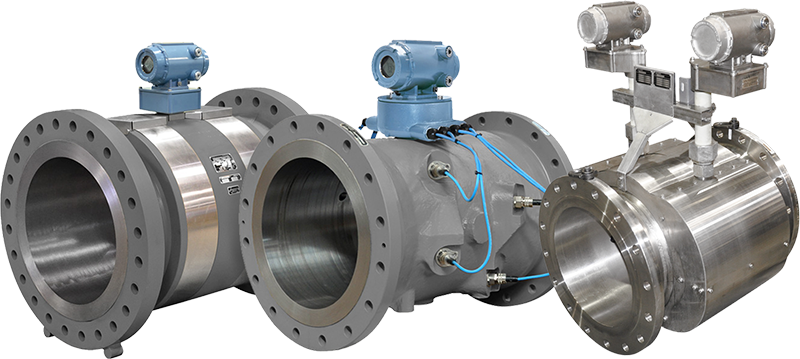

Rosemount Ultrasonic Flow Meter

Applications:

- Crude Oil and Refined Product Pipelines

- Custody Transfer

- Check Metering

- Allocation Measurement

- Leak Detection

- Line Balancing

- Loading and Offloading of Ships, Barges, and Rail cars

- Tank Farms

- Power Plant Inlets

- Gas Processing Plant

- Underground Storage Sites

Specifications:

- Line Sizes: 4″ to 24″ (DN100 to DN600)

- Sense Path Options: 2, 4, 8 Path

- Fluid Type: Liquid

- Linearity:

- Standard: ± 0.15% of measured value over a 1.2 to 12.2 m/s (4 to 40 ft/s) range

- Optional: ± 0.20% of measured value over a 0.6 to 12.2 m/s (2 to 40 ft/s) range

- Uncertainty of Meter Factor: < ± 0.027% (API MPMS, Chapter 5, Section 8, Table B-1)

- Velocity: 0.6 to 12.2 m/s (2 to 40 ft/s) with an extended range of 0.3 to 14.6 m/s (1 to 48 ft/s)

- Operating Temperature Range:

- Transducers: -50°C to +100°C (-58°F to +212°F) or optional -50°C to +150°C (-58°F to +302°F)

- Electronics: -40°C to +60°C (- 40°F to + 140°F)

- Operating Pressure Range: Up to 2,250 PSIG (0 to 155 Bar)

- Materials: Carbon Steel and Stainless Steel

- Voltage: 10.4 VDC to 36 VDC, 8 watts typical; 15 watts maximum

Features:

- Custody transfer accuracy and repeatability with high-capacity data logs for accountability and auditing

- High rangeability of >100:1 ensures fewer meter runs, smaller line sizes and lower capital costs

- Full bore design eliminates incremental pressure drop and reduces energy costs

- No flow conditioner reduces compression and pumping costs and eliminates maintenance due to blockages

- No moving parts reduce maintenance costs and eliminate periodic calibration unless required by local metrology authorities or company guidelines

- Field replaceable non-wetted transducers reduce downtime

- 3810 Series Electronics provide fast sampling and output, an expandable electronics platform, and an archive data log with detailed hourly and daily information

- Local LCD display (optional) with up to ten user-selectable scrolling variables

- Bi-directional flow capabilities simplify installation and reduce startup time

- Meter Link diagnostics software allows access to expert flow analysis and provides an intuitive view of meter health

- Predictive diagnostics are communicated, and variable information is processed allowing plant personnel to quickly detect and respond to abnormal situations to avoid process

upsets and unscheduled downtime

In applications where high accuracy, low pressure drop, reduced down time, and minimal static build up are critical, the Liquid Ultrasonic Meter has no equal. This instrument’s performance is based on the acoustic transit time principle, where changes to an ultrasonic pulse are recorded as they are transmitted through the product. It has no moving parts that can wear or fail. By eliminating the points of failure, it also reduces the potential for lost revenue from unaccounted product.

Ultrasonic meters are particularly well suited for cavern storage where there is heavy debris in the product and bidirectional flow is required. No matter what application applies to your business, the Liquid Ultrasonic Meter will meet and exceed your measurement needs.