Rosemount Radar Tank Gauging Systems

Applications:

- Tanks Storage Terminals

- Refineries

- Aviation Fuel Depots

- Lube Oil Depots

- Fuel Containment Storage Tanks for LNG and Other Liquefied Gases

- Petrochemical Industries

- Vegetable Oil Depots

- Distilleries

- Power Plants

- Steel Mills

- Leak Detection

Specifications:

- Accuracy: +/- 0.5 mm (+/- 0.020 inch.)

- Repeatability: 0.2 mm (0.008 inch)

- Update Rate: New measurement every 0.3 second

- Maximum Level Rate: Up to 200 mm/s

- Communication Protocol: Foundation™ Fieldbus or Modbus

- Power:

- FISCO: 9.0 – 17.5 VDC Polarity Insensitive

- Entity: 9.0 – 30.0 VDC Polarity Insensitive

- Line Size: 1.5 in – 12 in (Dependent on Antenna Type)

- Pressure Range: ANSI 150 to 300

- Temperature Range: -40 to +158 °F (- 40 to +70 °C) (High and Low Temp Options Available)

- Connection Type: Welded, Clamped / Threaded, ANSI Flange, Clamp Flange

- Approvals: OIML R85, ATEX, FM, EAC

- Safety Approvals: SIL 2 and SIL 3 Certified

- Antenna Types: Parabolic, Still-Pipe Array, Horn, LPG / LNG

- Redundancy: 2-in-1: Dual Independent Radar Level Gauge Electronics

- Warranty Options: 3 years or 5 years from date of shipment

Features & Options:

Temperature

- Rosemount 2240S Multi-input Temperature Transmitter – Ultra-stable temperature measurement. Connects up to 16 spot temperature sensors for average liquid temperature measurement and online temperature stratification monitoring

- Rosemount 565, 566, 765, and 614 Sensors – Four-wire calibrated temperature sensors and free water level measurement. Up to 16 Pt-100 spot elements per sensor/transmitter

- Rosemount 644 Temperature Transmitter – For single-point temperature measurement

- Rosemount 214C Single Point Temperature Sensors – For single-point Pt-100 temperature measurement

Pressure

- Rosemount 3051S Pressure Transmitter – Enables online density, mass, and vapor pressure measurement

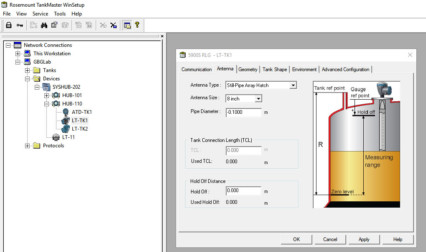

Communication & Accessories

- Rosemount 2410 Tank Hub – Collects and transfers data from one or several tanks. Enables emulation, wireless communication and SIL certified overfill prevention

- Rosemount 2460 System Hub – Transfers tank gauging data to TankMaster Inventory Management System and to Host/DCS

- Rosemount 2230 Graphical Field Display – Remote data access at tank top or ground level

- Rosemount 2100 Series Liquid Level Switch – Alternative option with point level switch when gauge in constant operation is not used for overfill prevention

- Rosemount 2180 Field Bus Modem – Used for connecting a TankMaster PC to the TRL2 field bus (if not using the system hub)

- Wireless Gateway – Connects wireless self-organizing networks with any host system

- Wireless 775 THUM Adapter – Adds wireless to all measurement points

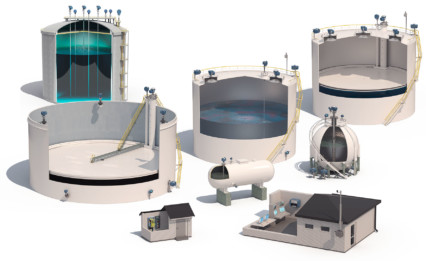

System Overview

The Precision Instruments of Tank Gauging

When you’re talking about SAAB Rosemount Tank Gauging you’re talking safety, accuracy, and reliability. These gauges are easily adapted for use on tanks with fixed or floating roofs. Pressurized versions are available for LPG spheres and gauges with parabolic antennas have been designed for difficult applications such as asphalt and crude oil.

Radar Gauges can be used as a standalone device with local indication or integrated into a DCS or Scada System. Communication support ranges from Fieldbus and Plantweb to Hart, OPC, and Profibus. Moreover, emulation modules have evolved allowing the SAAB Rosemount Radar Gauge to be used with existing competitive systems. When a corrected volume or mass balance is required these liquid level gauges can be used in combination with pressure transmitters, water level probes, and temperature sensors.

Documents & Additional Information

Rosemount Tank Gauging System Data Sheet

Rosemount Tank Gauging System Configuration Manual

Rosemount 5900S Radar Level Gauge Data Sheet

Rosemount 5900S Radar Level Gauge IOM

Rosemount 2240S Multi-Input Temperature Transmitter

Rosemount 565 / 566 / 765 / 614 Temperature and Water Level Sensor Data Sheet

Rosemount 3051S Pressure Transmitter Data Sheet

Rosemount 2410 Tank Hub Data Sheet

Rosemount 2460 System Hub Data Sheet

Rosemount 2230 Graphical Field Display Data Sheet

Rosemount 2120 Level Switch Data Sheet