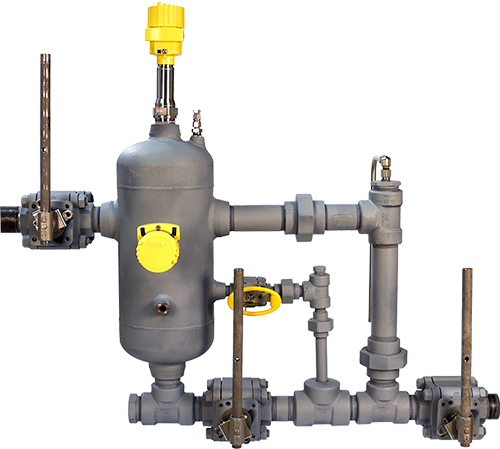

Pump Seal Monitoring

Applications:

- API Plan 65 Containment Vessel for Heavy and Medium Hydrocarbon

- API Plan 76 for Light Hydrocarbon

Specifications:

- Fluid: Liquid (Heavy Crude to Light Oil)

- Accuracy: +/-2 mm (21 Drops per Minute of Water)

- Operating Pressure Range: ANSI 150

- Capacity: 3 Gallon (Other options available)

- Area Classification: Class 1, Division 1, Groups C & D

Features:

- Continuous monitoring by non-contact radar

- Easy trending of pump seal performance

- Vibrating fork level switch for secondary output

- Full two inch unobstructed flow path

- Local display

- Easy calibration

Every Once in awhile Something Comes Along that Takes Things to the Next Level

Preventative Maintenance

The LIMECO Pump Seal Monitor is all about predicting failure rather than simply responding to it. With a flooded system, any fluid entering the containment vessel is at a predetermined level. Continuous monitoring of this level allows you to quickly identify changes that are outside of normal operating parameters. The LIMECO Pump Seal Monitor also allows you to understand the rate of failure, which is a critical metric when determining the best time to shut down for repairs. Our Leak Detection System gives you the information needed to be proactive without using disruptive alarms that require immediate attention.

It Has to Work

Two different and highly reliable technologies are used to monitor the containment vessel. The primary instrument is a non-contact radar level gauge. The accuracy of this gauge allows you to look at drops of product rather than in inches of water column. You will now be able to detect changes that were previously hidden from view. The gauge is located above the product and away from the flow path. This keeps it from touching the product, making it ideal for crude oil applications. The secondary instrument is a fork switch. It is positioned to react just prior to the containment vessel overflowing to drain. This unique combination of instruments makes the LIMECO Pump Seal Monitor the most reliable device on the market.

Made for the Real World

Pump seal monitors have to work in a range of environments, and some of them are going to be tough. Product is going to carry debris which can plug small orifices inside the seal monitor. For this reason the vessel is positioned to act as a settling tank with the orifice run off set to the side. Debris falls to the bottom and into the drain where it cannot affect the performance of the monitor.