Daniel Nitrogen Loaded Surge Relief Valves

Applications:

- Back Pressure Control

- Pipeline Pump Station Bypass

- Pipeline Surge Relief

- Manifold Pressure Control

- Tank Farm Inlet

Specifications:

- Line Size: 2” to 16” (N50 to DN400)

- Fluid Type: Liquid

- Operating Temperature Range: -15°F to +400°F (-26°C to +205°C) (Other Options Available)

- Operating Pressure Range: ANSI 150 to 600 (900 lb. ANSI Available Upon Request)

- Materials (Valve Body): Carbon Steel, ASTM A352 GR LCC

- Materials (Valve Cylinder):

- 2″ to 4″: Stainless Steel, ANSI 150 to 600

- 6″ to 16″: Carbon Steel, Nickel Coated, ANSO 150 to 600

- Materials (Valve Piston): Stainless Steel

- Materials (Seat Ring):

- 2″ to 6″ Stainless Steel

- 8″ to 16″ Carbon Steel, Nickel Coated

- Materials (O-Rings):

- Standard: Viton Dynamic and Buna-N Static

- Optional: Neoprene, EPR, Viton GFLT, all Buna-N, Kalrez®, Teflon AP

- Maximum Velocity: 58ft/sec

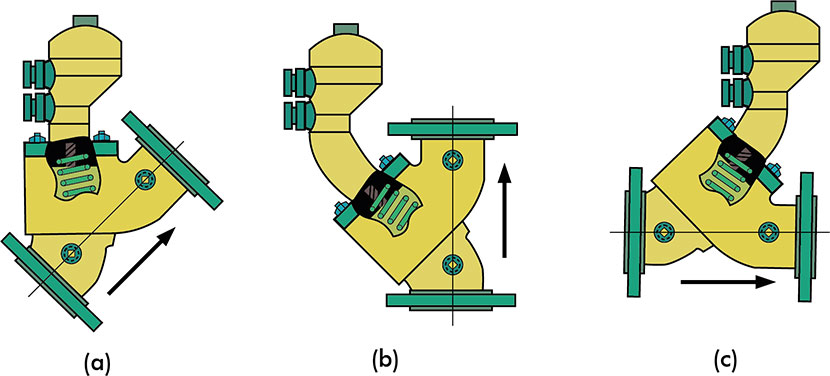

- Service Configuration Type: 45 Degree (Model 763), Vertical (Model 767), and Horizontal (Model 765)

Features:

- Fastest speed of response on the market

- Modular construction with balanced piston design

- Positive shut-off (ANSI Class VI)

- No blow down

- No pilot controls, diaphragms, or stuffing boxes

- Can pass dirty or viscous products

- 45° Piston design allows for valve body to stay in line for service

- High flow capacity

- Oil reservoir to prevent nitrogen seepage across the seals

- Screwed seat rings on all sizes

- Fail-safe closure upon power loss

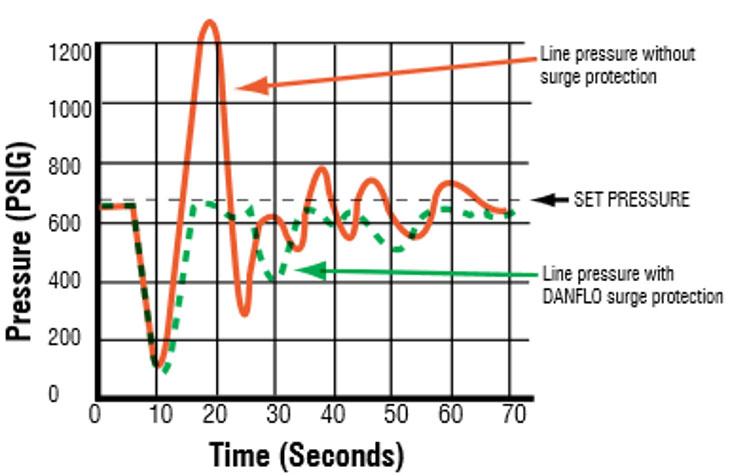

Surge relief is one of the most critical aspects of liquid pipeline design. Whether the application is a pipeline manifold, loading facility, or storage terminal, there is a need to protect critical equipment and personnel from the potential damage that can be caused by pressure surges. It is important to design a system that can quickly handle the entire wave of a surge.

The Daniel Model 765 Nitrogen Loaded Surge Relief Valve was designed to offer the fastest speed of response over other piston, pilot operated, or rubber sleeve designs. With the highest Cv flow rates of any valve on the market, it quickly becomes an obvious choice for virtually any surge relief application. Its unique design allows a lubricating oil to be added behind the main piston. This ensures a clean environment for the valve piston to travel and minimizes nitrogen migration across the internal seals.

When the Daniel Surge Relief Valve is combined with the LIMECO EZ® Nitrogen Regulating Panel and Limeco Ceramic Bead Plenum you get the best point stability, repeatability, and reliability on the market.